- Learn what an asphalt hot box is and why it's crucial for pothole patching and other pavement repairs.

- By the end of the article, you'll learn how to identify different types of hot box for asphalt, such as stationary and trailer mounted hot boxes.

- The box's capacity, insulation material, and temperature controls are essential factors to consider when purchasing one.

Welcome to Asphalt Kingdom's comprehensive asphalt hot box buying guide. This article will walk you through the different types of asphalt hot boxes available in the market, as well as the key factors you should consider to make an informed purchase.

Let’s dive in and get you one step closer to making the right choice.

What is an Asphalt Hot Box?

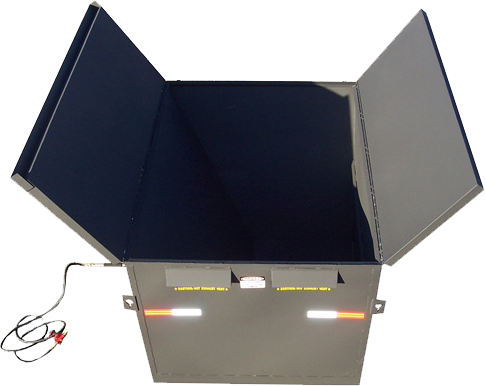

Asphalt Kingdom's Asphalt Hot Box for Sale

Asphalt Kingdom's Asphalt Hot Box for Sale

An asphalt hot box is a specialized piece of equipment used for carrying, maintaining, and distributing hot mix asphalt for pavement repair.

It is an insulated and temperature-controlled container typically mounted on a trailer or truck. It is designed to keep the asphalt at the desired temperature for a prolonged period. It ensures the asphalt remains workable during transportation from the plant to the job site.

This container is essential for road maintenance crews and asphalt maintenance contractors as it allows them to carry out asphalt repairs efficiently.

The Importance of Asphalt Hot Boxes

Asphalt Paving Street Resurfacing

Asphalt Paving Street Resurfacing

Hot boxes play a crucial role in asphalt maintenance and repair by enabling the transportation and use of hot mix asphalt at its optimal temperature.

Maintaining correct asphalt temperature is essential for achieving high-quality and durable repairs. Here’s how hot boxes contribute to asphalt maintenance and repair.

Maintaining Optimal Temperature. Asphalt needs to be at a certain temperature to be workable and to ensure proper compaction.

Hot boxes are insulated and equipped with heating systems to maintain the asphalt at the desired temperature during transportation and on the job site.

Flexibility. Hot boxes allow maintenance crews and contractors to transport hot mix asphalt from the plant to various job sites without worrying about the asphalt cooling down and becoming unworkable.

Efficiency. Having asphalt at the optimal temperature and ready to use on-site eliminates the downtime associated with waiting for new asphalt to be delivered or reheated. This increases the efficiency of repair operations.

Quality Repairs. Using asphalt at the correct temperature ensures proper compaction and bonding with the existing surface, resulting in high-quality, long-lasting repairs.

Cost-Effective. By maintaining the asphalt at the right temperature, they help minimize waste associated with cooled, unusable asphalt and helps contractors save money.

Related: The Best Material to Fill Potholes (+ How to Fix Potholes)

Types of Asphalt Hot Boxes

Asphalt hot boxes are designed to fit different needs and applications. Here are the most common types available in the market.

These are hot boxes mounted on a trailer and can be towed by a truck or a large vehicle. They are portable and ideal for small to medium-sized repair jobs.

The Asphalt Kingdom AK4000 Asphalt Hot Box is a good example of a trailer-mounted hot box. It can accommodate up to 2 tons of asphalt, making it a great choice for contractors who want to carry more asphalt to the job site. Read more about the AK4000 here.

Or check out the video below to learn more about the Asphalt Kingdom AK4000 Hot Box.

AK4000 Asphalt Hot Box

Truck-Mounted Hot Boxes

These asphalt containers are mounted directly onto the bed of a truck. They are suitable for larger repair jobs as they usually have a higher capacity than trailer-mounted hot boxes.

Stationary Hot Boxes

These are designed to be placed at a fixed location, like an asphalt plant or a maintenance yard. They are ideal for large-scale operations or locations where asphalt is needed regularly.

Hook-Lift Hot Boxes

These are designed to be lifted onto and off a truck using a hook-lift system. This design allows for flexibility as the same truck can be used for different purposes by changing the attachments.

Dumping Hot Boxes

These hot boxes have a hydraulic dumping feature that allows for easy unloading of the asphalt. This feature is available in both trailer-mounted and truck-mounted hot boxes.

What to Consider When Buying an Asphalt Hot Box

AK Hot Box

AK Hot Box

Capacity

Selecting the right capacity is crucial for the efficiency of your asphalt repair jobs. There are large units out there. But most asphalt hot boxes typically have a capacity that ranges from 2 to 7 tons.

A larger capacity hot box will allow you to transport more asphalt, reducing the number of trips back to the asphalt plant.

However, it is also important to consider the size and accessibility of the job sites. A larger hot box may not be suitable for narrow or hard-to-reach areas.

Additionally, consider the frequency of your jobs. If you have frequent small jobs, a smaller capacity hot box might be more efficient.

Related: How to Fill a Pothole in 4 Steps

Insulation

Insulation is essential for maintaining the asphalt at the desired temperature during transportation and on the job site.

Good insulation will minimize heat loss, reducing the energy required to maintain the asphalt temperature and ensuring the asphalt remains workable for a longer period.

Look for a hot box with high-quality insulation and a design that minimizes thermal bridges.

Heating System

There are different heating systems available for hot boxes, including propane, diesel, and infrared.

Propane and diesel heaters are the most common and are usually more cost-effective. Infrared heaters provide more even heating but are usually more expensive.

Consider the availability and cost of the fuel in your area, as well as the environmental impact.

Temperature Control

Accurate temperature control is crucial for quality asphalt repair. Overheating the asphalt can cause it to degrade, while insufficient heating can lead to poor compaction and bonding with the existing surface.

Choose a hot box with an accurate and easy-to-use temperature control system.

Durability and Maintenance

A durable hot box with low maintenance requirements will reduce your long-term costs and downtime.

Pick a hot box with a robust design and high-quality components. Additionally, consider the availability of replacement parts and the manufacturer's after-sales service.

Additional Features of an Asphalt Hot Box

Manual worker laying asphalt at road construction site

Manual worker laying asphalt at road construction site

When selecting an asphalt hot box, it's important to consider some additional features that may be beneficial for specific needs.

Tack Tank. A built-in tack tank can be a very useful feature for contractors who frequently apply tack coat during repair jobs.

Having a tack tank integrated with the hot box eliminates the need for a separate tack distributor, saving space and making the operation more efficient.

Compactor Carrier. This feature allows you to carry a compactor with the hot box, which is essential for compacting the asphalt after it has been laid.

A compactor carrier eliminates the need for a separate vehicle to transport the compactor, making the operation more efficient and cost-effective.

Hydraulic Dumping. A hydraulic dumping feature allows for easy unloading of the asphalt, saving you and your crew time and labor.

This feature is especially beneficial for larger repair jobs where a significant amount of asphalt needs to be unloaded.

Shovel Cleaning Door. A shovel cleaning door allows for easy cleaning of the hot box after use. This is essential for maintaining the container in good condition and ensuring its longevity.

Thermometer. An external thermometer allows for easy monitoring of the asphalt temperature, which is crucial for ensuring the quality of the asphalt repair.

Agitator. An agitator helps to keep the asphalt mix homogeneous during transportation, ensuring consistent quality across the entire batch.

Choosing the Right Asphalt Hot Box Supplier

Urban road under construction while asphalting in progress

Urban road under construction while asphalting in progress

Selecting an asphalt hot box supplier is as important as choosing the right equipment.

A reliable supplier will not only provide a high-quality hot box, but also offer good after-sales service and support.

Here are some pointers on choosing the best asphalt hot box supplier.

1. Quality Assurance. Reputable asphalt hot box suppliers have a track record of providing high-quality equipment that meets or exceeds industry standards.

They often have quality certifications and conduct rigorous testing to ensure the reliability and performance of their hot boxes.

2. Parts Availability. Availability of replacement parts is crucial for maintaining your hot box in good working condition.

The supplier should have a well-stocked inventory of parts and can ship them quickly when needed.

Related: Make Money All Winter Long Doing Urgent Pothole Repair

3. Warranty. The best hot box supplier will offer a comprehensive warranty that covers defects in materials and workmanship.

This provides peace of mind and ensures that any issues will be addressed promptly and at no additional cost.

4. Expertise. Ideally, the supplier should have a team of experts who can provide valuable advice and support.

Whether it is helping you select the right hot box for your needs or providing training on its operation and maintenance, their expertise can be invaluable.

5. Customer Feedback. Good suppliers often have positive customer feedback and testimonials online.

This is a good indication of their commitment to customer satisfaction and the quality of their products and services.

Conclusion:

Ready to purchase your first 2-ton asphalt hot box? We're here to help. Talk to our asphalt equipment specialists by giving us a call at 1-866-399-5562 or send a message to sales@asphaltkingdom.com.