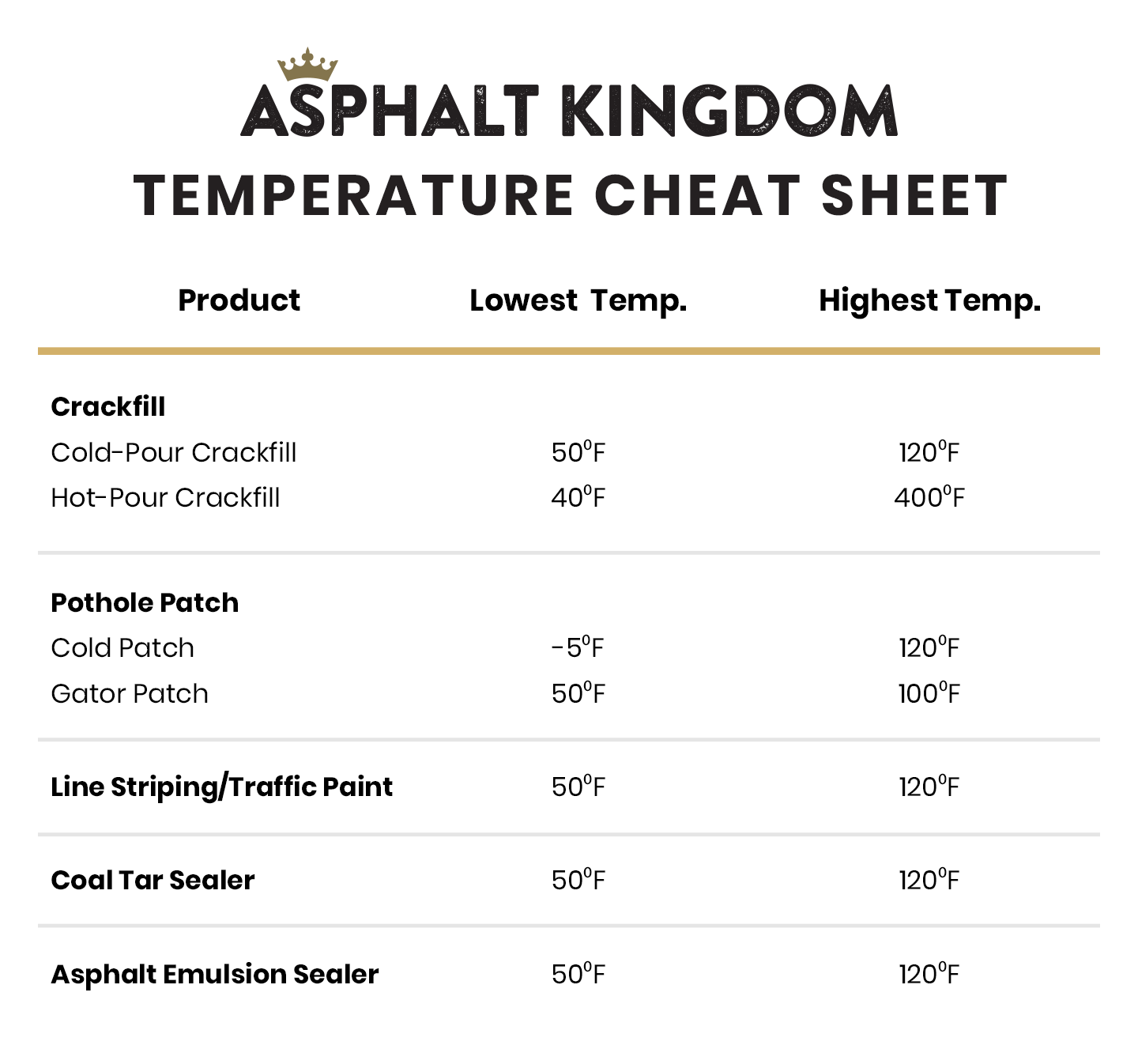

Knowing what the ideal job temperature is before applying crack fill, sealcoat or line striping paint is essential in making sure your project lasts. Planning your scheduled jobs and being up to date on weather forecasts is important so you don’t sacrifice the quality of your work because of less-than-perfect temperatures.

Right-click to save image

Additional Notes and Information

Crackfill

The common misconception is that crack sealing can only be done when the weather is warm. However, this is not the case entirely. While it is ideal to seal cracks during spring and fall, it is also possible to do so during colder days – even during winter! Regardless of the actual ambient temperature, so long as the cracks are dry and heated to at least 40⁰F to 50⁰F using a torch or hot air lance, you can apply asphalt crack filler.

For cold-pour crack filler, the maximum ambient temperature should be less than 120⁰F to make sure that the material adheres to the cracks properly. If the temperature is hotter, the crackfill can melt and not bond properly. For hot-pour crackfill, maximum kettle temperature can be up to 400⁰F, which is the maximum heating capacity of the product, without ruining its bonding capability.

Not many know this, but crackfill actually dries faster during cold weather – so long as no rain is expected within 24-48 hours after application. This means that you can seal cracks very early or very late into the season, and use the time in between to work on other projects that require warmer weather – such as sealcoating and line striping.

If you need to determine how much crackfill you’ll need in your projects, you can use our crack filler calculator for free. For our best methods and techniques on crack sealing, check out our crack repair page today!

Pothole Patch

Potholes form when hairline cracks on the pavement surface are not filled or sealed in a timely manner. As the aggregate base becomes weaker due to moisture penetration, the surface layer sags and crumbles, leaving sunken hollows on the pavement. The larger these holes grow, the more it will cost to get them fixed. Patching holes on the pavement before they can get worse is a wise investment, as this will prevent further damage and costs less than repaving or resurfacing.

Asphalt Kingdom offers two different types of pothole patches depending on the type of pothole that needs to be fixed.

The cold asphalt patch repair is ideal for year-round use since this product can be applied even if the weather is -5⁰F, and as long as it does not exceed 120⁰F. So long as the cold patch is tamped down and compacted properly with either a hand-held pothole tamper or a mechanized vibrating plate compactor, this repair option will hold for a long time.

The Gator Patch, on the other hand, is ideal for a web-like network of shallow cracks that do not exceed ½ inch deep. This product works best on temperatures ranging from 50⁰F to 100⁰F.

For a comprehensive guide on pothole repair, be sure to check out our resource page!

FREE DOWNLOAD!

Get your FREE ebook on how not to ruin your asphalt

Line Striping Paint

Whether you are repainting over faded lines or applying fresh stripes on a new lot, it is wise to know what the best weather and climate conditions are. Generally, it is not recommended to paint traffic lines if the temperature is below 40⁰F, making 50⁰F the ideal base temperature. If the weather is too cold, the line striping paint can dry up really fast, making each stripe uneven and flaky. It is also not recommended to paint if the temperature exceeds 120⁰F for the same reasons. For a speedy job with accurate markings, we suggest using stencils when applying line striping paint.

Check out our line striping page for tested and proven methods to ensure that your customer is satisfied with your output. Feel free to use our paint calculator to help you determine how much material you’ll need to get the job done.

Asphalt Emulsion Sealer

Asphalt emulsion sealer should only be applied if the ambient temperature is at least 50⁰F and rising. Pavement temperature should be at least 60⁰F and rising. It is not recommended to apply sealer during rainy or overcast days with high humidity. Moisture on the work surface would not allow the sealer to adhere to the asphalt properly. The weather forecast should be sunny and dry for at least 48 hours after application to ensure proper bonding and longevity.

Before applying the sealer, check that the pavement temperature is not beyond 120⁰F. Fog spraying is recommended, as it helps cool the pavement down enough without melting the sealer during application. Spray just enough water to cover without puddling.

Sealcoating is highly recommended to further protect the asphalt surface from getting penetrated by moisture from rain and melted snow. Visit our sealcoating guide for our best techniques in sealcoating, and use our sealer calculator to help you determine how much sealer you’ll need to finish your job.

If you are working on a very large project, we also offer spot sealer delivery with a tanker to your job site! This option not only saves you time, it also saves you money and manpower. Just send us a request for a quote, and we will work with you for a hassle-free delivery.

Additives

Additives help sealer dry faster and provides a sleeker and darker finish. However, those are not the only reasons why additives are a great investment into your sealcoating jobs. Additives help sealers bond better and allow for better dispersion when using sand in the mix. Since there are different types of sealers available on the market, there are also different types of additives that can highly improve your output compared to just applying sealer by itself.

According to Adam Wellman of Maintenance Inc., “Using additives adds a whole different dimension to your sealer. It encapsulates sand, if you are using a sand load” which helps in better mixing and dispersion. He also explains that additives “add flexibility to different types of sealcoat, especially the asphalt emulsion, which always has a hard time to bond” with asphalt pavements. But most importantly, it can reduce drying and curing time, so it extends your spring and fall season.

FSA Fast Sealing Additive can help reduce drying and curing time for sealer

Now that you have a handy guide on the most ideal temperature ranges for the products that you use on the job, it is up to you to ensure that your crew members adhere to these industry-standard templates. Actual results may slightly vary depending on the brands used, however, the output should be pretty much uniform so long as these acceptable temperature ranges are observed and followed.